Laser cutting technology is widely used in the processing of metal and non-metal materials, which greatly reduces processing time, reduces processing costs and improves workpiece quality. What should be paid attention to in laser cutting metal processing? Below, QIAOLIAN GROUP will introduce to you the precautions when using the double table laser cutting machine.

1. It is strictly forbidden to start the machine without grounding, and all parts of the machine are completely grounded to prevent static electricity from hurting people.

2. After each startup, check whether the submersible pump has water. If there is no water, it is strictly forbidden to start the pump.

3. Ensure that the circulating water has a moderate water temperature, and the water quality is dry and free of debris (purified water is recommended). Change the circulating water regularly (7 days).

4. Use a special camera lens paper or a medical cotton swab dipped in a mixture of alcohol and ether to wipe the reflector and focusing mirror. (The mixing ratio of ether and alcohol is 1:1)

5. Be sure to turn on the fan when engraving, so as not to contaminate the lens and focusing lens.

6. It is strictly forbidden to place flammable and explosive materials near the laser machine equipment. When the machine is working, cover the top cover of the machine to prevent the laser deviation from causing fire or hurting people.

7. During the working process of the machine, the operator is forbidden to leave without authorization to avoid unnecessary losses.

8. Non-professionals are strictly prohibited from disassembling the machine without authorization to avoid accidents.

9. It is strictly forbidden to place any irrelevant reflective objects in the equipment to prevent the laser from being directly reflected on the human body or flammable objects, causing danger.

10. It is forbidden to start the machine when the voltage is unstable, otherwise use a voltage stabilizer.

11. Untrained personnel are prohibited from using the laser engraving machine.

12. During the working process of the machine, the operator should observe the working conditions of the machine at any time (such as: whether the paper laid on the edge is blown up by the air pump to block the laser, the machine makes an abnormal sound, the temperature of the circulating water, etc.).

13. The environment where the machine is located has no interference and influence from strong electricity and strong magnetism.

14. The continuous working time of the machine should not exceed 5 hours (break for more than half an hour in the middle).

15. It is strictly forbidden to turn on the ammeter at a large value, so as to avoid breakdown of the laser power supply.

16. Basic restrictions on the use of laser power (that is, the ammeter cannot exceed 20mA)

17. If the machine fails or fire occurs, please cut off the power immediately.

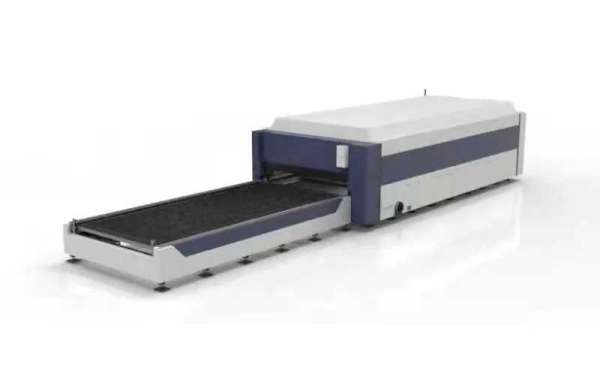

The double-table laser cutting machine produced by QIAOLIAN GROUP is a fully enclosed structure, impeccable safety, excellent safety performance, strong cutting ability, high stability, breaking through the limit of difficult welding of vertical sections, challenging the limit of bevel cutting of thick plates, and equipped with intelligent control system. Power cutting head. It is a cost-effective laser cutting equipment with high configuration, high performance and high efficiency.

The first factory of QIAOLIAN GROUP started in Luoshe Town, Wuxi City, Jiangsu Province in 1998. After more than 20 years of development, it has been involved in CNC lathes, CNC machining services, plasma cutting machines, laser cutting and welding machines, automated production solutions and other fields. We are very experienced in the production and sales of CNC machinery and equipment, and we have operations all over the world, welcome to inquire!