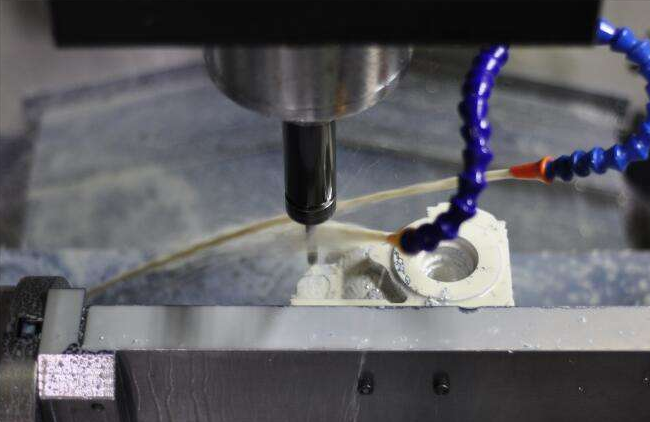

Machining that is done with tools that are controlled by a computer numerically controlled (CNC) system is what is meant when people talk about CNC machining, which is just another name for the same thing. CNC stands for computer numerically controlled, and it refers to a system that controls the tools that are used in machining. The term "CNC" refers to a system that controls the tools that are used in the machining process. CNC is an abbreviation that stands for "computer numerical control. "Machining with a computer numerically controlled (CNC) machine offers a number of benefits, some of which include a high degree of repeatability, consistent quality, high machining accuracy, and high machining efficiency. CNC machines are also known as numerical control machines. These advantages are a direct result of the fact that CNC machining is directed by a computer through the use of a predefined software application. This allows for greater precision and accuracy in the finished product. While the actual processing step is being carried out, the quality of the final processed product that is produced will be significantly influenced by a number of human factors as well as previous working experience. This is because the quality of the final processed product is directly related to how well the actual processing step was carried out.

Following the completion of the plane and the positioning surface, respectively, the step known as "the hole" is typically the next one in the processing order to be finished. After the plane is involved in the vast majority of these kinds of incidents. The processing starts with the geometric shape that possesses the least number of complex features, and cnc machining service then it moves on to the geometric shape that possesses the greatest number of complex features. The execution of these steps is something that must be done because of the characteristics of the approach.

In conclusion, in order to properly differentiate the process, it needs to be grasped in a flexible manner in accordance with the structure and craftsmanship of the custom cnc milling part, the function of the machine tool, the number of CNC machining contents of the part, the number of installations, and the production arrangement of the unit. This is necessary in order to properly differentiate the process. It is important to take into account each and every one of these aspects. It is critical to ensure that each and every one of these facets is taken into consideration.

Machining that is done with tools that are controlled by a computer numerically controlled (CNC) system is what is meant when people talk about CNC machining, which is just another name for the same thing. CNC stands for computer numerically controlled, and it refers to a system that controls the tools that are used in machining. The term "CNC" refers to a system that controls custom cnc milling the tools that are used in the machining process. CNC is an abbreviation that stands for "computer numerical control. "Machining with a computer numerically controlled (CNC) machine offers a number of benefits, some of which include a high degree of repeatability, consistent quality, high machining accuracy, and high machining efficiency. CNC machines are also known as numerical control machines. These advantages are a direct result of the fact that CNC machining is directed by a computer through the use of a predefined software application. This allows for greater precision and accuracy in the finished product. While the actual processing step is being carried out, the quality of the final processed product that is produced will be significantly influenced by a number of human factors as well as previous working experience. This is because the quality of the final processed product is directly related to how well the actual processing step was carried out.

Following the completion of the plane and the positioning surface, respectively, the step known as "the hole" is typically the next one in the processing order to be finished. After the plane is involved in the vast majority of these kinds of incidents. The processing starts with the geometric shape that possesses the least number of complex features, and then it moves on to the geometric shape that possesses the greatest number of complex features. The execution of these steps is something that must be done because of the characteristics of the approach.

In conclusion, in order to properly differentiate the process, it needs to be grasped in a flexible manner in accordance with the structure and craftsmanship of the part, the function of the machine tool, the number of CNC machining contents of the part, the number of installations, and the production arrangement of the unit. This is necessary in order to properly differentiate the process. It is important to take into account order cnc machined parts each and every one of these aspects. It is critical to ensure that each and every one of these facets is taken into consideration.

The factors that led to the failure have been isolated, and the investigation into the macroscopic and microscopic characteristics of the inner surface cracks of the alloy shell parts as well as the machining process of the parts has been finished. This allows for a comprehensive understanding of the failure and its causes. A number of chemical tests were performed on the crack in the defective part, and the results of those tests show that the quantity of each element that was present in the crack satisfies the criteria established by the relevant standards. The crack was found to be in compliance with the relevant standards.

Machining that is done with tools that are controlled by a computer numerically controlled (CNC) system is what is meant when people talk about CNC machining, which is just another name for the same thing. CNC stands for computer numerically controlled, and it refers to a system that controls the tools that are used in machining. The term "CNC" refers to a system that controls the tools that are used in the machining process. CNC is an abbreviation that stands for "computer numerical control. "Machining with a computer numerically controlled (CNC) machine offers a number of benefits, some of online machining services which include a high degree of repeatability, consistent quality, high machining accuracy, and high machining efficiency. CNC machines are also known as numerical control machines. These advantages are a direct result of the fact that CNC machining is directed by a computer through the use of a predefined software application. This allows for greater precision and accuracy in the finished product. While the actual processing step is being carried out, the quality of the final processed product that is produced will be significantly influenced by a number of human factors as well as previous working experience. This is because the quality of the final processed product is directly related to how well the actual processing step was carried out.

Following the completion of the plane and the positioning surface, respectively, the step known cnc machining services as "the hole" is typically the next one in the processing order to be finished. After the plane is involved in the vast majority of these kinds of incidents. The processing starts with the geometric shape that possesses the least number of complex features, and then it moves on to the geometric shape that possesses the greatest number of complex features. The execution of these steps is something that must be done because of the characteristics of the approach.

In conclusion, in order to properly differentiate the process, it needs to be grasped in a flexible manner in accordance with the structure and craftsmanship of the part, the function of the machine tool, the number of CNC machining contents of the part, the number of installations, and the production arrangement of the unit. This is necessary in order to properly differentiate the process. It is important to take into account each and every one of these aspects. It is critical to ensure that each and every one of these facets is taken into consideration.

The factors that led to the failure have been isolated, and the investigation into the macroscopic and microscopic characteristics of the inner surface cracks of the alloy shell parts as well as the machining process of the parts has been finished. This allows for a comprehensive understanding of the failure and its causes. A number of chemical tests were performed on the crack in the defective part, and the results of those tests show that the quantity of each element that was present in the crack satisfies the criteria established by the relevant standards. The crack was found to be in compliance with the relevant standards.

Machining that is done with tools that are controlled by a computer numerically controlled (CNC) system is what is meant when people talk about CNC machining, which is just another name for the same thing. CNC stands for computer numerically controlled, and it refers to a system that controls the tools that are used in machining. The term "CNC" refers to a system that controls the tools that are used in the machining process. CNC is an abbreviation that stands for "computer numerical control. "Machining with a computer numerically controlled (CNC) machine offers a number of benefits, some of which include a high degree of repeatability, consistent quality, high machining accuracy, and high machining efficiency. CNC machines are also cnc machining parts known as numerical control machines. These advantages are a direct result of the fact that CNC machining is directed by a computer through the use of a predefined software application. This allows for greater precision and accuracy in the finished product. While the actual processing step is being carried out, the quality of the final processed product that is produced will be significantly influenced by a number of human factors as well as previous working experience. This is because the quality of the final processed product is directly related to how well the actual processing step was carried out.

Following the completion of the plane and the positioning surface, respectively, the step known as "the hole" is typically the next one in the processing order to be finished. After the plane is involved in the vast majority of these kinds of incidents. The processing starts with the geometric shape that possesses the least number of complex features, and then it moves on to the geometric shape that possesses the greatest number of complex features. The execution of these steps is something that must be done because of the characteristics of the approach.

In conclusion, in order to properly differentiate the process, it needs to be grasped in a flexible manner in accordance with the structure and craftsmanship of the part, the function of the machine tool, the number of CNC machining contents of the part, the number of installations, and the production arrangement of the unit. This is necessary in order cnc milling online to properly differentiate the process. It is important to take into account each and every one of these aspects. It is critical to ensure that each and every one of these facets is taken into consideration.

The factors that led to the failure have been isolated, and the investigation into the macroscopic and microscopic characteristics of the inner surface cracks of the alloy shell parts as well as the machining process of the parts has been finished. This allows for a comprehensive understanding of the failure and its causes. A number of chemical tests were performed on the crack in the defective part, and the results of those tests show that the quantity of each element that was present in the crack satisfies the criteria established by the relevant standards. The crack was found to be in compliance with the relevant standards.

The processing technology and the operation methods for fine mechanical parts are both governed by a technology that is known as cnc fine parts processing technology. cnc stands for computer numerical control, and fine parts processing technology is a subset of cnc. The technology in question is one that fits into one of the categories that are associated with technology. Once it has been verified, it will be used as a point of reference throughout the entirety of the manufacturing process. On top of that, the process specification might also include a variety of other components. Processing precision mechanical parts has the potential to effectively increase labor productivity, increase the value of output, have higher economic benefits, and reduce the costs of the enterprise. All of these outcomes would be desirable. To get things moving, these are just some of the things that can be done.

There are many more. The processing of fine mechanical parts can also result in improved working conditions, a reduction in the intensity of labor, a reduction in the amount of time spent performing labor, and an increase in the level of civilized production. These benefits can be achieved by reducing the amount of time spent performing labor and reducing the amount of time spent performing labor. These benefits are attainable by lowering the total amount of time spent on manual labor and by lowering the total amount of time spent on manual labor. It is an efficient method for producing fine products in a wide variety of shapes, such as hollow cones, cylindrical parts, hemispheres, and thin-walled pipes, to name just a few of these available alternatives. In addition, it is a method that can produce fine products in a wide variety of sizes. When compared to the costs associated with producing an item using other methods, the cost of producing certain items using spinning is significantly lower. In addition, the tools and molds that are utilized in the process of spinning are straightforward and straightforward to replace. The longest production times, the lowest output value, and the limited type options are the most significant flaws in the product.

After this research has been completed, some recommendations for how it could be improved in the future will be made. Chemical analysis was performed on the crack in the defective part, and the results showed that the quantity of each element present in the crack satisfies the requirements of the applicable standards. The crack was considered cnc machining parts to be structurally sound. The fracture of the defective part was examined through the course of the test. The initial processing technology for 2A12 aluminum alloy shell parts included the steps of blanking, car center hole (F65), heat treatment (quenching + natural failure), car inner hole (F140), and failure. These steps comprised the initial processing technology. The processing technology was unsuccessfully completed at the failure stage. These stages make up the initial processing technology, which can be broken down into its constituent parts.

5 millimeters in thickness just before it is put through the process of heat treatment. This information was found as a result of the investigation into the defective heat-treated parts, which led to the investigation's discovery of the information. This was done so that the finished product would be of the highest possible quality, and it was successful in achieving that goal. The temperature inside the open-air furnace has now reached 495 degrees Fahrenheit. This provides proof beyond a reasonable doubt that inadequate heat treatment was the cause of the cracking that can be seen on the interior surface of the component, and that this cracking was caused by the component being improperly cooled. The study of the processing technology that was used to manufacture the flawed part reveals that when the processing reaches the portion of the part where there was insufficient heat treatment and the previous milling parts online cutting speed and cutting amount are kept, the stress concentration at the tool tip acts on the accumulation of the strengthening phase at the grain boundary, which results in crack distribution along the strengthening phase. This was discovered through the study of the processing technology that was used to manufacture the flawed part. This was uncovered through the investigation of the processing methodology that was utilized during the production of the defective component. This information was uncovered as a result of an investigation into the processing technology that was used in the manufacturing of the flawed component.