SnO2 based sensors has received extensive attention in the field of toxic gas detection due to their excellent performances with high sensitivity, fast response, long-term stability. Volatile organic compounds (VOCs), originate from industrial production, fuel burning, detergent, adhesives, and painting, are poisonous gases with significant effects on air quality and human health. This mini-review focuses on significant improvement of sno2 compound name based sensors in VOCs detection in recent years. In this review, the sensing mechanism of SnO2-based sensors detecting VOCs are discussed. Furthermore, the improvement strategies of the SnO2 sensor from the perspective of nanomaterials are presented. Finally, this paper summarizes the sensing performances of these SnO2 nanomaterial sensors in VOCs detection, and the future development prospect and challenges is proposed.

Introduction

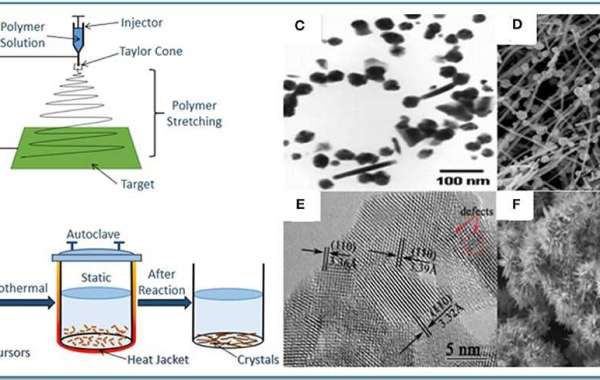

Carbon materials and metal oxide semiconductor materials like SnO2, ZnO, WO3, and In2O3 have received scientific and technological importance and are widely used to detect VOCs gases. SnO2 gas sensor has been extensively studied for its applications in air quality detection, flammable and explosive gas detection, and environmental monitoring. Nanomaterials have become the focus of the best sensing materials in recent years. Nanomaterials have many natural advantages such as large specific surface area, small size, and lightweight. At present, there are many kinds of structures such as nanowires, nanofilaments, nanowires hollow spheres, nanofilaments flowers, and nanotubes. Different nanostructures and morphologies have different effects on the properties of materials. In order to change the nanostructure of a single material, there are other ways to improve the gas sensitivity of the sensor. This mini-review summaries the gas-sensing performances of sno2 compound name based sensor, which were influenced by the microstructure, doping, oxide composite and noble metal modification, toward toluene (C6H5CH3), formaldehyde (HCHO), and acetone (C3H6O).

Sensing Mechanism of SnO2 Gas Sensor

SnO2 sensor is a surface-controlled gas sensor. The gas-sensing reaction can only cause changes in parameters such as surface conductivity of the semiconductor. When exposed to air, oxygen molecules would be adsorbed on the surface of the sno2 compound name nanostructures and capture electrons from the conduction band of sno2 compound name to generate chemisorbed oxygen species, depending on temperatures.

When SnO2 sensor contacts with the measured gas, its resistance will change according to the oxidation or reduction characteristics of the gas. Toluene, formaldehyde and acetone tested in this paper are reductive gases. When SnO2 material surface comes into contact with a reducing gas, the reducing gas will react with oxygen anions to produce carbon dioxide and water, and the resulting electrons will return to the conduction band of the semiconductor. Therefore, this process will increase the carrier concentration on the surface of SnO2 material, resulting in a decrease in the resistance value. When finally restored to the air environment, the sensor returns to its original state. The sensing mechanism of the SnO2 sensor reacting with these gases can be represented by the following path.