During the use of CNC metal laser cutting machine, there will be a problem that the gap between cutting sheet metal materials is too wide. How should we deal with this common problem? We can start from the following three aspects.

1. The operating engineer must first check the focal length of the CNC metal laser cutting machine to see if the focal length is correct, and adjust it in time if any errors are found. At the same time, it should be noted that the methods of adjusting the focal length are divided into manual and automatic. Manual focus adjustment is easy to be forgotten. After replacing or cleaning the lens, the operating engineer should carefully check the focal length;

2. If there is no problem with the focal length, you can check the lens first. The large slit can also be avoided by checking the lens in the CNC metal laser cutting machine. If the surface of the lens is stained, it will also affect the cutting of the material, and the lens is not clean. It is easy to scatter and thicken the light, so it is a good choice to check the lens for cleaning or replacement;

3. The placement of the laser tube is also a very important aspect. If there are bright spots in the light spot or the light spot is not round, it may be that the support point of the laser tube needs to be adjusted. Many people will ignore this reason, which needs attention.

The precision of the metal laser cutting machine depends entirely on the equipment itself, and is composed of many factors. The quality of a machine is often determined by its accuracy.

The shape of the laser beam is an important factor that affects the accuracy of metal laser cutting machines. We all know that the laser beam is tapered, so the slits cut out are also tapered. In this case, the thin plate with a thickness of 0.3mm will be much smaller than the slit of 2mm. Therefore, the greater the thickness, the better the cutting accuracy. lower.

In addition, the cutting format, the material to be cut, and the worktable will all affect the accuracy of the metal laser cutting machine. The smaller the width of the slit, the higher the cutting accuracy; the high-precision workbench also helps to improve the cutting accuracy of the metal laser cutting machine!

In the process of using the CNC metal laser cutting machine, some mistakes will inevitably occur, and this requires customers to do a good job in the maintenance of the CNC metal laser cutting machine, so as to extend the maximum working time of the CNC metal laser cutting machine equipment. , to create greater value, and at the same time, if there is a problem, you can directly contact the manufacturer to solve the problem.

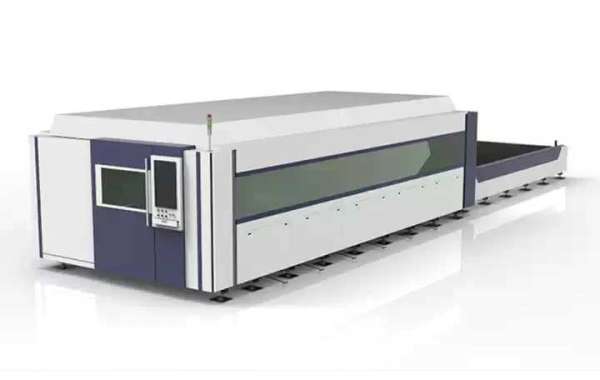

CNC Metal Laser Cutting Machine Supplier - Qiaolian Cylion

The gantry large-format laser cutting machine provided by QIAOLIAN GROUP for the majority of factories is a flexible processing of super-large-format thick plates and segmented splicing beds, and the format can be customized on demand; the bed and worktable are designed separately. In order to ensure the high dynamic performance of the machine tool and the service life of the machine tool, it can adapt to workpieces with a width of 3200mm and a thickness of 50mm. With high cost performance and users to seek win-win development, welcome all new and old customers to come to consult!