Faced with all kinds of CNC laser tube cutting machines on the market, have you been dizzy and don't know where to start? Expensive ones are not necessarily good, but only laser tube cutting machines suitable for your business are useful. Qiaolian Cylion will share with you how to choose a cost-effective laser tube cutting machine.

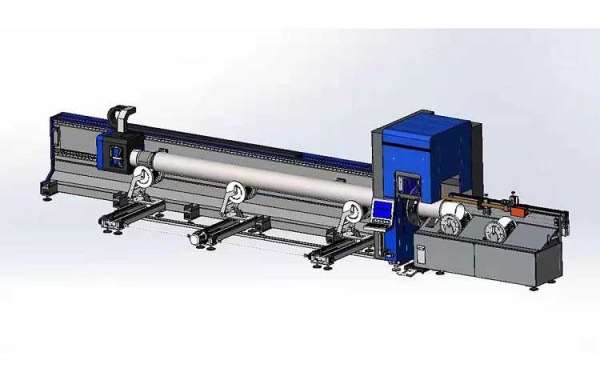

The appearance of laser tube cutting machine has greatly shortened the production cycle of bevel cutting of tube fittings and sheet metal parts. It is widely used in automobile manufacturing, machinery manufacturing, tube processing and other industries. Laser tube cutting machine technology is an advanced metal processing method. In the tube processing process, laser tube cutting machine can complete various types of tube processing at high speed, and the processing effect is better than traditional technology. It has been widely recognized by various industries.

The selection of laser tube cutting machines is mainly based on the size of the cutting volume and the requirements of cutting accuracy. At present, the laser tube cutting machines on the market can be divided into: manual tube cutting machine, semi-automatic tube cutting machine, automatic tube cutting machine, intelligent tube cutting machine, and the output is also increasing in order. Of course, there is also laser cutting, but the cost of laser cutting is too high, and the cost performance is not high. By the way, it is worth mentioning the intelligent tube cutting machine, which is a new type of tube cutting machine that has only emerged this year, that is, the intelligent tube cutting machine. Once it came out, it has been favored by various tube cutting machine manufacturers, and it is more suitable for mass production.

Characteristics that the CNC laser tube cutting machine needs to have

First of all, the first point is to save materials: the head and tail of the material can be automatically identified and cut off.

Secondly, the second point is high precision: control settings + mechanical positioning, the cutting accuracy is as high as plus or minus 0.05mm±.

The third point is to save labor: fully automatic, only need to manually place the tube on the material rack, and the rest is fully automatic, one person can control multiple machines at the same time.

The fourth point, high efficiency: the average time for a knife is two to three seconds.

Finally, the fifth point is the cutting effect: no burrs, smooth and smooth, no need for secondary processing.

One of the greatest benefits of using a laser tube cutter is that it can make intricate cuts faster than other machines. For example, punching holes in tubes of various shapes and sizes, cutting various graphics. In addition, laser tube cutting can provide a good cutting section, and no secondary treatment is required for subsequent welding and other processing, which is equally applicable to the cutting of thin-walled and thick-walled tubes. What really sets laser-cut tubing apart is the precision of the cut, and industrial manufacturing applications involving small-diameter tubing have been greatly accelerated thanks to improvements in modern laser cutting machines.

CNC Laser Tube Cutting Machine Exporter - Qiaolian Cylion

Qiaolian Cylion has always been rigorous and responsible, striving for perfection, constantly updating and improving our production equipment, testing system and testing equipment, and striving for excellent quality. In the future development, we will bring "better products and more professional services" to our customers!