After Mitutoyo decided to invest in 10 rotary tables, RPI UK, a specialist developer and manufacturer of precision positioning devices for high accuracy rotary and CMM Inspection Companies inspection systems, welcomed the Japanese manufacturer as a new customer. RPI UK is a developer and manufacturer of precision positioning devices for high accuracy rotary and angular inspection systems.

Mitutoyo, one of the leading manufacturers of precision measuring cmm services in the world, has integrated three QuadMatic and seven QuadSlimLine rotary tables into its high precision co-ordinate measurement machines (CMM) at its Japanese and UK operations. These CMMs were manufactured at Mitutoyo's facilities in Japan and the United Kingdom. Engineers from RPI traveled to Japan to assist Mitutoyo with training and maintenance. While they were there, they also assisted with the integration of a two-axis rotary table at Mitutoyo's location in Halifax, United Kingdom.

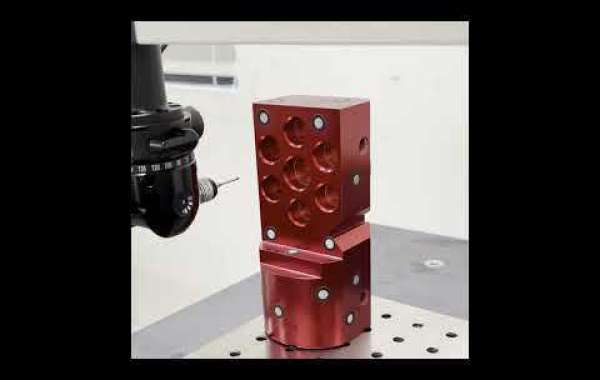

The rotary tables offered by RPI are an excellent complement to high precision CMMs. They are accurate to within +/- 0.5 arc seconds and were developed specifically for use as a fourth axis.

"It's great news that Mitutoyo has chosen to invest in 10 of our Quadrant range rotary tables," said Jim Palmer, who is in charge of sales at RPI. Our rotary tables not only result in a significant improvement in overall measurement accuracy and a reduction in uncertainty, but they also result in a significant increase in measuring volume, CMM Inspection Companies which in turn results in an improvement in the adaptability, productivity, and efficiency of our customers' coordinate measuring machines (CMM).

RPI now supplies all of the major CMM manufacturers that use rotary tables, from Hexagon to Renishaw and LK to Wenzel, thanks to the addition of Mitutoyo to its customer base. RPI is a manufacturer based in Bath. Since 1977, RPI has been a supplier for the CMM market, and the company has a record of more than 750 successful installations across the globe.

RPI's Quadrant range of CMM tables, which also includes the QuadDualPurpose, QuadProfile, and the QuadUniversal, includes the QuadSlimLine and the QuadMatic as two of its components. They are available in a wide range of sizes, ranging from 200mm to 1500mm, and they are able to be fully integrated with the host CMM machine controller.

RPI is a company that originated from the merger of several other companies, including Optical Measuring Tools, Airmatic, Horstmannn, and Eimeldingen. It is now one of the largest designers and manufacturers of solution-driven, highly accurate inspection systems and services that measure circular geometry and angular positioning in the world. These systems and services measure circular geometry and angular positioning. RPI supplies progressive engineering industries, such as the aerospace industry, the gas turbine industry, and the dimensional metrology industry, with products that are extremely dependable, require very little maintenance, and have a service life that is measured in decades rather than years. RPI has been in the rotary business for 75 years.

TPP Is Proud To Announce The Launch Of Their New Compliance Management Module, CMM 4.1 CMM 4.1 Features An Improved Graphical User Interface Along With Numerous Feature Updates Suitable For All User Levels

End-users can analyze individual part data, flagging, cmm inspection services and supporting documentation, roll-up reports, and generate product-level compliance certificates from a single location using the Dashboard, which provides executives with a high-level view of the overall status of the project.

CMM 4.1 delivers the critical data required to satisfy legal and customer requirements while TPP's data team ensures that completeness and accuracy are maintained on all parts. This is made possible thanks to TPP's "People, Not Just Software" approach to environmental compliance declaration and reporting services.

According to Keith Biggs, the Chief Executive Officer of TPP, "a large percentage of supplier declarations contain errors or missing data.""In order to provide the necessary data, certain suppliers require training. In other instances, the only way to derive the actual substances that make up things like zinc, polymers, and chromates is by looking at the drawing. Someone will need to either walk your suppliers through the process or place a set of eyes on those drawings in order to determine the substances, so it's important to remember that it's people, not software, that will be needed.

CMM 4.1 provides users with access to clean and actionable data, ensuring that businesses are always prepared for instantaneous analysis, PLM integration, roll-up and reporting for material declarations, RoHS, REACH, Conflict Minerals, Prop 65, and other regulations.

When it comes to Total Parts Plus:

Total Parts Plus (TPP) is an industry leader in the provision of parts data content for the purposes of product environmental compliance and lifecycle management. Along with our suite of cloud-based applications, TPP's data collection and validation services provide a comprehensive solution for data analysis and compliance reporting.

TPP is committed to providing its customers with a compliance reporting service that is highly accurate, innovative, and efficient in its use of resources. TPP is able to provide full compliance traceability, ongoing data management, and monitoring of legislative changes because of its close relationships with manufacturers, industry groups, and suppliers. This ensures that the company's reporting is as accurate as possible.