Fixing of the seal

In principle, the fixation of seals is divided into two categories: adhesive fixation and non-adhesive fixation. The shape of the gasket should be consistent with the shape of the seal of the plate heat exchanger. It must be pointed out that the adhesive fixing method does not have any effect on the sealing function.

non-adhesive seal

Alignment: Putting the seal in place

Insertion: Make the seal ring enter the seal groove correctly

Compression: In the sealing groove. There is a groove-shaped structure with a gradually decreasing cross-section. In order to make the sealing ring correctly positioned

Adhesive seals can use blended sealants and non-blended sealants from different manufacturers according to the purpose of use of the gasket and the quality requirements of the seal. Before bonding, the residual adhesive and residual gasket on the bonding surface should be thoroughly removed by the steam flow.

For the bonding of the blended sealant, the residual adhesive and residual gasket on the joint surface of the plate heat exchanger must be burned out with fire. When bonding in large quantities, a liquid nitrogen pool for freezing seals should be prepared, and a heating furnace for drying treatment of plate heat exchangers with gaskets should be prepared, and the heating temperature should reach 160 °C. If possible, the plate heat exchanger should be chemically cleaned to ensure that the gaskets of the bonding parts remaining in the joint surface of the plate heat exchanger are completely removed.

According to the observation hole of the honeycomb of the plate heat exchanger to know whether the sealing gasket is installed correctly Softener and anti-stick coating on pads, apply adhesive to the middle of each bonded surface.

Depending on the width of the gasket, the width of the adhesive is about the width of a match, and then use a brush to spread the adhesive evenly on the entire bonding surface so as to make full use of the entire bonding surface. Depending on the type of adhesive, wait for a certain period of ventilation and drying, then put in the gasket, stack the plate heat exchangers together, and tighten them with tensioning screws, or press them with heavy objects on the stacked heat exchangers. on the heater pack.

Depending on the type of adhesive, the hardening time is about 8-20 hours. For blended adhesives, screw tightening and furnace heating and hardening must be carried out.

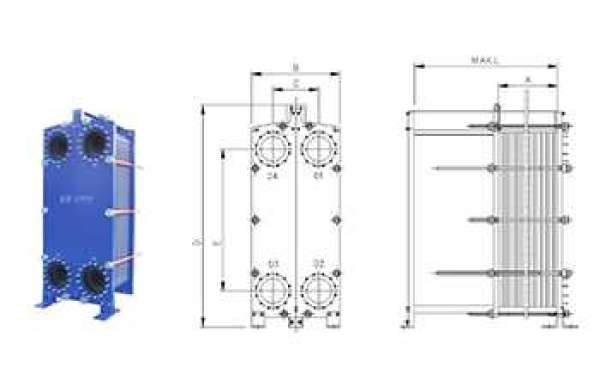

Jiangsu Yuanzhuo Equipment Manufacturing Co., Ltd. is a professional manufacturer of plate heat exchangers. Plate heat exchangers are widely used. We have Brazed Plate Heat Exchangers and Gasketed Plate Heat Exchangers. If you are interested in plate heat exchangers, please feel free to contact us to 0086-510-86165907 or send an email to zy@jsyuanzhuo.com.