Marine waste and overflowing landfills have attracted widespread attention to the plastic waste we discharge into the environment. In response, communities around the world are striving to reduce, reuse, and recycle. But what does recyclability mean? A research group led by Liu Guoliang, an associate professor of chemistry at the University of Science, is trying to expand the frontiers of plastic recycling.

Many of us throw a metal or glass can into the recycling bin without thinking. But plastic is a bit different. Not every recycling plant has equipment to handle various types of plastics. This is because the chemistry and structure of plastic materials are diverse, and each type requires a specific recycling procedure.

In a perfect world, there may be recycling factories around the world that can handle all kinds of plastics you can think of. But we haven't achieved this yet, partly because some plastics are difficult to recycle and we haven't developed effective and practical technologies to handle them.

Polystyrene is such a challenging material. Polystyrene is the main component of polystyrene foam, which is widely used, but rarely recycled. Many municipal recycling facilities instruct residents (including those in Blacksburg) not to put polystyrene in their recycling bins at home.

At present, the main method of recovering polystyrene often produces products with low quality, making the process economically infeasible. In other words, if a recycling factory attempts to recycle polystyrene on a large scale, it either needs financial support, such as government subsidies, or there is a risk of running out of funds and going bankrupt.

One solution to this problem is to improve the recycling process to make it economically feasible, even better, and economically attractive. With his experience in polymer chemistry and as a member of the Institute of Macromolecule Innovation, this is exactly what Liu can guide his team to do.

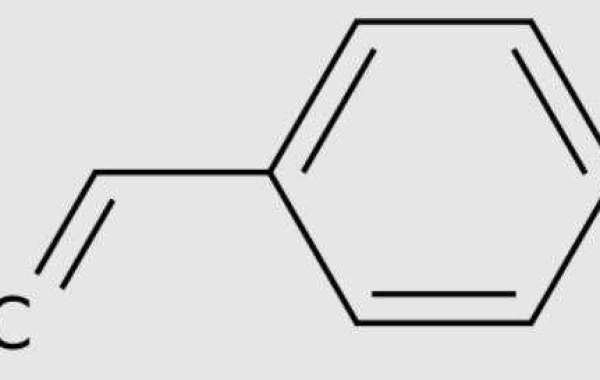

In a recent paper published in the Proceedings of the National Academy of Sciences, the team proposed a new method for recycling polystyrene, or more accurately, "upgraded recycling". By exposing the material to ultraviolet light and adding a chemical catalyst, this method produces a very useful product called diphenylmethane (DPM). DPM is used as a precursor for drug development, polymer manufacturing, and even as a spice in consumer goods. Importantly, the market price of DPM is 10 times higher than other materials made of recyclable polystyrene at present.

The researchers took their research one step further: they wanted to confirm that this new method could achieve the economic feasibility they pursued. Chemists from Virginia Tech collaborated with business experts from Santa Clara University and Northeastern University of Finance and Economics to conduct an analysis to determine the overall profit of this recycling method. Their results indicate that due to the high economic value of DPM, the cost of collecting and processing polystyrene is completely reasonable.

This new recycling method will incentivize the collection and recycling of polystyrene, rather than entering landfills or becoming plastic contaminated.

I think it's important for people to realize that there may be multiple solutions to major global challenges like plastic waste, and it's very likely that multiple solutions are needed, "Liu said." We at Virginia Tech can contribute a small part to this big challenge and provide solutions that have a positive impact on the world.”