The construction industry, known for its scale and complexity, has historically relied on manual labor and traditional methods to build structures. However, with the advancement of technology, a new era is dawning upon the Robotics in Construction Market. Integrating robotics in construction processes has the potential to revolutionize the industry, unleashing unprecedented levels of efficiency, safety, and productivity.

Understanding Robotics in the Construction Market

In the context of construction, robotics refers to the use of automated machines, drones, and artificial intelligence to perform tasks that were previously done by human labor. These robotic systems are designed to mimic human movements and intelligence, enabling them to execute tasks with precision and accuracy.

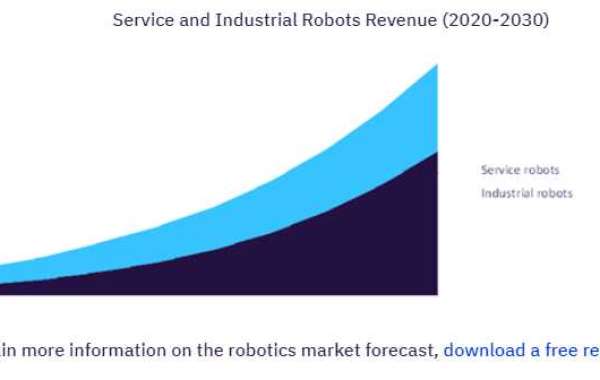

To gain more information on the robotics market forecast, download a free report sample

Advantages of Implementing Robotics in Construction

3.1 Increased Efficiency and Productivity

One of the primary benefits of employing robotics in construction is the significant increase in efficiency and productivity. Robots can work tirelessly, 24/7, without the limitations of human fatigue, resulting in faster project completion and reduced construction timelines.

3.2 Enhanced Safety Measures

Safety is a paramount concern in the construction industry. By leveraging robotics for hazardous tasks such as demolition, excavation, and working at heights, companies can minimize the risks to human workers, ensuring a safer work environment.

3.3 Precision and Accuracy

Robots are equipped with advanced sensors and technologies that enable them to carry out tasks with remarkable precision and accuracy. This ensures that construction projects are executed to the highest standards, reducing rework and associated costs.

3.4 Cost Savings and Sustainability

While the initial investment in robotics may be substantial, the long-term cost savings are significant. Robots streamline processes, reduce material wastage, and optimize resource utilization, making construction projects more sustainable and financially viable.

Key Areas of Robotics Implementation in Construction

4.1 Automated Equipment and Machinery

Automated machinery such as robotic arms and exoskeletons can assist workers in heavy lifting and repetitive tasks, reducing physical strain and increasing overall productivity.

4.2 Drones and Aerial Surveillance

Drones equipped with cameras and sensors can monitor construction sites, track progress, and identify potential issues from above, providing real-time data for informed decision-making.

4.3 Autonomous Vehicles and Transportation

Self-driving vehicles can transport materials and equipment around the construction site efficiently, minimizing delays and optimizing logistics.

4.4 3D Printing and Prefabrication

3D printing technology allows for the rapid production of building components, enabling faster construction and greater design flexibility.

Addressing Challenges in Adopting Robotics in Construction

5.1 Initial Investment and Training Costs

Implementing robotics in construction requires significant upfront investment in technology and training. Companies need to assess the long-term benefits and potential ROI before making this transition.

5.2 Integration with Existing Workforce

Companies must plan for a seamless integration of robots into the existing workforce. Training and upskilling workers to collaborate with robotic systems will be crucial for success.

5.3 Regulatory and Legal Implications

As the use of robotics in construction is relatively new, there are still regulatory and legal challenges to navigate. Companies need to ensure compliance with safety and privacy regulations.

The Future of Robotics in Construction

6.1 Continued Technological Advancements

The field of robotics is constantly evolving, and we can expect even more sophisticated and specialized robotic systems designed specifically for construction purposes.

6.2 Collaboration between Humans and Robots

The future will likely see humans and robots working collaboratively, with robots handling dangerous and repetitive tasks, while humans focus on complex decision-making and creativity.

6.3 Transforming the Construction Industry

Robotics will reshape the construction industry, leading to increased efficiency, reduced costs, and a more sustainable approach to building.

Case Studies: Real-World Applications of Robotics in Construction

7.1 Robotic Bricklaying: Fastbrick Robotics

Fastbrick Robotics has developed a robotic bricklaying system capable of laying bricks at an astonishing speed, revolutionizing the bricklaying process.

7.2 Drones for Construction Site Mapping: Skycatch

Skycatch utilizes drones equipped with high-resolution cameras and LiDAR technology to create detailed 3D maps of construction sites, enabling better planning and management.

7.3 Autonomous Construction Equipment: Built Robotics

Built Robotics has designed retrofit kits that turn standard construction equipment into autonomous machines, allowing construction tasks to be carried out with minimal human intervention.

Ethical Considerations and the Human Factor

8.1 Impact on Jobs and Workforce

The widespread adoption of robotics in construction may raise concerns about potential job displacement. Companies must address these concerns and explore ways to reskill and redeploy workers.

8.2 Ensuring Ethical Use of Robotics

Clear guidelines and ethical standards should be established to govern the use of robotics in construction, ensuring that they are utilized for the greater good of society.

Embracing the Robotic Revolution: Recommendations for Businesses

9.1 Conducting a Comprehensive Cost-Benefit Analysis

Before integrating robotics into construction processes, businesses should conduct a thorough cost-benefit analysis to understand the potential advantages and challenges.

9.2 Providing Training and Support to Workers

Investing in training programs for the workforce will enhance their adaptability and ensure a successful transition to working alongside robotic systems.