What is Thermoplastic Polyurethane (TPU)?

Within thermoplastic elastomers, thermoplastic polyurethanes (TPU) form a subcategory. As a rule, these materials are block copolymers of polyethers or polyesters with classic polyurethanes.

Different material properties are usually adjusted during polymerization by combining different raw materials. In rare cases, subsequent compounding with various additives is also carried out.

What properties does a Thermoplastic polyurethane material have?

Thermoplastic polyurethane materials are characterized primarily by their high mechanical strength and very good abrasion resistance.

Plastics from the Thermoplastic polyurethane class show good resistance to various non-polar chemicals. In contrast, there is a certain sensitivity of the materials with regard to material degradation in contact with water and aqueous solutions, especially at high temperatures. To avoid material damage, it is therefore essential to dry Thermoplastic polyurethane compounds before processing. This also supports the processability of the materials.

Depending on the manufacturer, Thermoplastic polyurethane are also produced for the consumer market. The materials can be colored, and some manufacturers also offer translucent TPU.

Are Thermoplastic polyurethane hard or soft?

The hardness grade of thermoplastic polyurethanes is usually between 60 Shore A and 80 Shore D. Compared to typical TPS products, TPU materials are significantly harder and rarely compete with each other directly.

Does KRAIBURG TPE produce Thermoplastic polyurethane?

KRAIBURG TPE does not manufacture TPU itself and does not sell these plastics. However, various TPU are used as property brokers and modifiers in styrene-based thermoplastic elastomers.

Thermoplastic polyurethane TPU

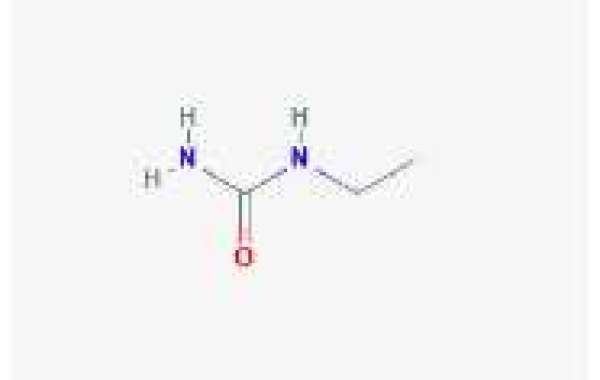

TPU thermoplastic polyurethane is abbreviated as TPU or TPE-U. It is a polymer made up of a chain of organic units connected by carbamate (urethane) links.

Thermoplastic polyurethane materials come in many types, depending on the composition of the polyols and isocyanates used. Thermoplastic polyurethanes based on esters are distinguished by high resistance to mineral oils and wear. They are also characterized by high tensile strength and high elasticity. By using other raw materials such as polyester, it is possible to significantly increase the resistance of the material to low temperatures and hydrolysis. Other changes allow to increase the resistance to the action of biodegradable oils, such as synthetic esters. The gas permeability of thermoplastic polyurethane is comparable to that of IIR rubber.

What does the abbreviation Thermoplastic polyurethane stand for?

The abbreviation TPU comes from the English language. It stands for thermoplastic polyurethane, i.e. thermoplastic polyurethane.

Thermoplastic polyurethane – properties

Thermoplastic polyurethane has a heat resistance of up to around 80 degrees. Special materials achieve a heat resistance of up to 100 Celsius, short-term even up to 120 degrees.

Its resistance to low temperatures reaches even 45 degrees Celsius below zero.

Moreover, Ultrathan is not brittle in the face of low temperatures. Thus, O-rings made of it are not damaged by mechanical stress, even below the glass transition temperature.

Characteristic properties of Thermoplastic polyurethane are also: good flexibility and elasticity, the ability to deformation back, shock and shock absorbing properties, tear and crack resistance, good abrasion resistance.